Tough finish has long lasting abrasion and impact resistance. Mix for approximately 2 minutes using a slow speed drill and squirrel mixing paddle. Our latest blog is now available to read and we hope that it will be of interest to classic car owners or businesses who are looking for authentic and elegant black and silver number plates.Third generation family business, Simpson & Co, is local to us here in Stoke-on-Trent. Thoroughly vacuum the first coat after sanding and remove any dust particles etc. It is a heavy duty concrete coating system that easily roll applied. The self storage units along with other commercial units have been painting in the company colourorange! Clear coat is required when Deco-Flakes are used. Damaged surfaces must also be repaired, and the concrete may need to be ground to open up its pores and profile the surface. Once neutralising is complete, check the entire surface of the concrete. Simpson and Co have a facebook page and welcome any enquiries via 01782 212705 or Perhaps the main concern expressed by people considering usingEpoxy Garage Floor Paint on a project is a phenomenon called, in the trade, Hot Tyre Pickup otherwise known as Hot Tyre Lift. 12 | 8 Methods of Coating Thickness Measurement, 13 | Coatings Specifications, Good, Bad or Ugly: Lou Vincent Q&A, 14 | Coating Holidays & Pinholes: Chinks in the Armor, Corrosion Resistance in Reinforced Concrete Structures, a popular choice in garages in the automotive industry, 6 Ways to Measure Surface Profiles for Concrete Surface Preparation, The History and Industry Adoption of Polyurea Coating Systems, while the initial cost of acrylic floor coatings may be relatively inexpensive, long-term maintenance costs tend to be higher, Corrosion Prevention Substance Characteristics, An Intro to Pipeline Corrosion and Protection Methods, Polyurea Coating Spotlight with Kyle Flanagan, Review of Solvent-Free Epoxy Protection for Secondary Containment Concrete, Why Concrete Delamination Occurs - and What to Do About It. Reposted from @phoenix_church_conversion Bought an orange container.but thought it might scare the neighbours so tried to make it look more inconspicuous! Pack Size: Part A = 7.5 L & Part B = 2.5 L. I used this clear epoxy coating on my garage floor last year and it still looks like new. Although these valves exhibit slightly higher pressure

Allow the acid to bubble on the concrete for up to 15 mins. Acrylic floor coatings are not as durable as their epoxy or polyurethane counterparts. Before acid etching, make sure the concrete is cleaned properly of all contaminants, oil, grease and dirt by using the. This product is not suitable for external application. In some cases it may be necessary to use a concrete grinder or a light acid wash. Basically, if water does not penetrate through the contamination then neither will a sealer or a coating. We are passionate about championing businesses such as Simpson and Co. A link to set a new password will be sent to your email address. Share your thoughts about this product with other customers, write a review. Suitable for heavy duty commercial and industrial areas. Dilute the hydrochloric acid with water at a rate of 1 part acid to 10 parts water. Please ensure you check your calculations as Right Choice Coatings cannot be held responsible if the incorrect quantity. After 24 hours, remove the plastic.  We answer those questions for []. #regalpaintuk #epoxyfloorpaint #madeinbritain #floorpaint #makeitbritish Well done to Jez who is the recipient of a 50 Amazon eVoucher! See MoreSee Less.

We answer those questions for []. #regalpaintuk #epoxyfloorpaint #madeinbritain #floorpaint #makeitbritish Well done to Jez who is the recipient of a 50 Amazon eVoucher! See MoreSee Less.  By: Krystal Nanan

Suitable for heavy duty commercial and industrial areas.

By: Krystal Nanan

Suitable for heavy duty commercial and industrial areas.  Our single pack floor paint options includeAnti-Slip Floor Paint,Concrete Floor Paint,Garage Floor Paint andHigh Build Floor Paint. - Hard Drying Time:48 hrs

Floors coated with this material can be ready for operation the next day. Another benefit of polyaspartic floor coatings is its ability to be customized. Tough finish has long lasting abrasion and impact resistance. Allow to stand for 1 minute & then mix again for 1 minute. oil, grease, bird droppings etc. Here we answer the most commonly asked questions, [], Two-Pack Epoxy Floor Paint - Epoxy is our most hard-wearing and durable floor coating. The winner of our June #showusyourproject competition is a local flooring specialist, @purtfloor of Hartshill, Stoke-on-Trent. There are several questions that we are frequently asked by our customer. 80, Home of Industrial Protective Paints Ltd, manufacturers of Regal Paint. Krystal is a civil engineer and project manager with an MSc

Using our two-pack epoxy floor paint system in light grey @purtfloor has done a top quality job at Solutions Engineering Ltd in Trentham.The floor was prepped and then primed with the epoxy sealer coat, before being finished with the top coat in light grey.Well done to Jez who is the recipient of a 50 Amazon eVoucher!You can browse our winning #showusyourproject competition entries on our website and also find details of how to enter.If you are interested in our floor paints, please head over to our website bit.ly/3js4JcD or call us on 01782 550733.#regalpaintuk #industrialprotectivepaintsltd #showusyourproject #floorpaint #greyfloorpaint #epoxyfloorpaint #epoxypaint #epoxy #FloorContractors #skill #purtfloor

Here [], Single Pack Floor System - Our popular single pack paint system will give you a long-lasting and quality finish to your floor. We intend to clad the container when we have finished the church and keep it as a shed! Just look at that LED wall!!! - Coverage: 5-7 m per litre

Allow the surface to dry for a minimum of 24 hours (weather dependant). management of major infrastructure projects, construction supervision, and the

The more air flow and warmer conditions, the quicker the epoxy will cure. Allow at least 12 hours to dry between coats, but no more than 48 hours. Written by

DO NOT MIX WITH PIGMENTS OR ANY OTHER ADDITIVES. Ensure that it is free from any tears or pinholes (this would render the test useless). As you can see from the photographs, our parlour paint has fantastic opacity and can coat various substrates (this unit had breezeblock and wooden cladding).If you have a project and are in need of paint advice and technical help, please don't hesitate to give us a call on 01782 550733.Well done to Orland on being this month's winner of a 50 Amazon Voucher!Wishing you all the very bestAll the team at Regal Read the blog here https://bit.ly/2TROmgt

Required fields are marked *. Fax: 1-800-867-8246 We are official distribution partners for Remmers as well as major stockists of Newton Membranes. Primers are helpful because they are able to penetrate the pores of the substrate (e.g. Time the amount of time it takes for the water to soak into the concrete. Apply the diluted solution evenly to the surface using a watering can or similar. Quick Dry Garage Floor Paint - A single pack quick dry floor coating, giving good durability against abrasion and impact with protection against solvent, salt and water damage.

Our single pack floor paint options includeAnti-Slip Floor Paint,Concrete Floor Paint,Garage Floor Paint andHigh Build Floor Paint. - Hard Drying Time:48 hrs

Floors coated with this material can be ready for operation the next day. Another benefit of polyaspartic floor coatings is its ability to be customized. Tough finish has long lasting abrasion and impact resistance. Allow to stand for 1 minute & then mix again for 1 minute. oil, grease, bird droppings etc. Here we answer the most commonly asked questions, [], Two-Pack Epoxy Floor Paint - Epoxy is our most hard-wearing and durable floor coating. The winner of our June #showusyourproject competition is a local flooring specialist, @purtfloor of Hartshill, Stoke-on-Trent. There are several questions that we are frequently asked by our customer. 80, Home of Industrial Protective Paints Ltd, manufacturers of Regal Paint. Krystal is a civil engineer and project manager with an MSc

Using our two-pack epoxy floor paint system in light grey @purtfloor has done a top quality job at Solutions Engineering Ltd in Trentham.The floor was prepped and then primed with the epoxy sealer coat, before being finished with the top coat in light grey.Well done to Jez who is the recipient of a 50 Amazon eVoucher!You can browse our winning #showusyourproject competition entries on our website and also find details of how to enter.If you are interested in our floor paints, please head over to our website bit.ly/3js4JcD or call us on 01782 550733.#regalpaintuk #industrialprotectivepaintsltd #showusyourproject #floorpaint #greyfloorpaint #epoxyfloorpaint #epoxypaint #epoxy #FloorContractors #skill #purtfloor

Here [], Single Pack Floor System - Our popular single pack paint system will give you a long-lasting and quality finish to your floor. We intend to clad the container when we have finished the church and keep it as a shed! Just look at that LED wall!!! - Coverage: 5-7 m per litre

Allow the surface to dry for a minimum of 24 hours (weather dependant). management of major infrastructure projects, construction supervision, and the

The more air flow and warmer conditions, the quicker the epoxy will cure. Allow at least 12 hours to dry between coats, but no more than 48 hours. Written by

DO NOT MIX WITH PIGMENTS OR ANY OTHER ADDITIVES. Ensure that it is free from any tears or pinholes (this would render the test useless). As you can see from the photographs, our parlour paint has fantastic opacity and can coat various substrates (this unit had breezeblock and wooden cladding).If you have a project and are in need of paint advice and technical help, please don't hesitate to give us a call on 01782 550733.Well done to Orland on being this month's winner of a 50 Amazon Voucher!Wishing you all the very bestAll the team at Regal Read the blog here https://bit.ly/2TROmgt

Required fields are marked *. Fax: 1-800-867-8246 We are official distribution partners for Remmers as well as major stockists of Newton Membranes. Primers are helpful because they are able to penetrate the pores of the substrate (e.g. Time the amount of time it takes for the water to soak into the concrete. Apply the diluted solution evenly to the surface using a watering can or similar. Quick Dry Garage Floor Paint - A single pack quick dry floor coating, giving good durability against abrasion and impact with protection against solvent, salt and water damage.  If under 90 seconds then the concrete has sufficient porosity for application of the sealer. Recommended for areas receiving heavy traffic (vehicle/trucks). It provides excellent resistance to water, solvents, acids, alkalis and salts and gives superb adhesion to all recommended substrates. safety elements and drainage. Skip to the beginning of the images gallery. Epoxy coatings market, revenue (%), by end-user industry, global, 2018. How Can I Use Coatings to Prevent Corrosion? Regal Paintsare specialist manufacturers of, and more. If you are interested in our floor paints, please head over to our floor paint page. Polyurethane Concrete Floor Paint is easy to apply with a gloss or semi-gloss finish. Clear Epoxy Coatingfrom Right Choice is a solvent free, 100% solids epoxy (3:1 mixing rate). One of the primary benefits of polyaspartic is its ability to be used as a complete flooring system as well as a topcoat. #regalpaintuk #industrialprotectivepaintsltd #showusyourproject #floorpaint #greyfloorpaint #epoxyfloorpaint #epoxypaint #epoxy #floorcontractors #skill #purtfloor Our latest blog is now available to read and we hope that it will be of interest to classic car owners or businesses who are looking for authentic and elegant black and silver number plates. Suitable for light commercial and industrial areas. Concrete floor coatings offer unique properties and benefits that lend themselves to various applications. Their limited pot life and moisture sensitivity also make them challenging to work with. Many of these contaminates are easily removed using the Right Choice Concrete Cleaner. Once the spread rate is achieved, gently tip off the epoxy with the roller and move on to the next section. Surface preparation, in particular, can be tedious. After priming your floor surface, you are now ready to add a top coat of floor paint. | Civil Engineer, By: Steven Bradley

Do not park vehicles or place heavy equipment on the floor for a minimum of 48 hours

- Recoat: 24 hrs

Hot-dip vs Cold Galvanizing: Whats the Difference? Repeat the test over multiple sections of the concrete substrate. Specific acrylic formulations, however, can offer superior performance characteristics, such as enhanced UV protection, slip resistance and water resistance.

If under 90 seconds then the concrete has sufficient porosity for application of the sealer. Recommended for areas receiving heavy traffic (vehicle/trucks). It provides excellent resistance to water, solvents, acids, alkalis and salts and gives superb adhesion to all recommended substrates. safety elements and drainage. Skip to the beginning of the images gallery. Epoxy coatings market, revenue (%), by end-user industry, global, 2018. How Can I Use Coatings to Prevent Corrosion? Regal Paintsare specialist manufacturers of, and more. If you are interested in our floor paints, please head over to our floor paint page. Polyurethane Concrete Floor Paint is easy to apply with a gloss or semi-gloss finish. Clear Epoxy Coatingfrom Right Choice is a solvent free, 100% solids epoxy (3:1 mixing rate). One of the primary benefits of polyaspartic is its ability to be used as a complete flooring system as well as a topcoat. #regalpaintuk #industrialprotectivepaintsltd #showusyourproject #floorpaint #greyfloorpaint #epoxyfloorpaint #epoxypaint #epoxy #floorcontractors #skill #purtfloor Our latest blog is now available to read and we hope that it will be of interest to classic car owners or businesses who are looking for authentic and elegant black and silver number plates. Suitable for light commercial and industrial areas. Concrete floor coatings offer unique properties and benefits that lend themselves to various applications. Their limited pot life and moisture sensitivity also make them challenging to work with. Many of these contaminates are easily removed using the Right Choice Concrete Cleaner. Once the spread rate is achieved, gently tip off the epoxy with the roller and move on to the next section. Surface preparation, in particular, can be tedious. After priming your floor surface, you are now ready to add a top coat of floor paint. | Civil Engineer, By: Steven Bradley

Do not park vehicles or place heavy equipment on the floor for a minimum of 48 hours

- Recoat: 24 hrs

Hot-dip vs Cold Galvanizing: Whats the Difference? Repeat the test over multiple sections of the concrete substrate. Specific acrylic formulations, however, can offer superior performance characteristics, such as enhanced UV protection, slip resistance and water resistance.  * Unlike epoxy coatings, which are highly stiff and impact-resistant, polyurethane floor coatings are relatively softer and more elastic. If the epoxy produces a fine dust it is dry enough to sand, however if it is clogging up the sandpaper then you will need to wait longer for it to cure.

* Unlike epoxy coatings, which are highly stiff and impact-resistant, polyurethane floor coatings are relatively softer and more elastic. If the epoxy produces a fine dust it is dry enough to sand, however if it is clogging up the sandpaper then you will need to wait longer for it to cure.  Yes the Epoxy Floor Coating in clear can be used to seal and dustproof concrete floors, it will create a dust free water resistant floor coating which will leave the concrete slightly wet looking. The link is in our bio (profile information) and you can also copy and paste this link into your browser https://bit.ly/3de20RM. *, All images & photographs on this website are the copyright property Globe valves are named for their spherical body shape with the two halves of the body being separated by an internal baffle. Lightly dampen the surface so that the concrete is slightly wet but not puddling water. Don'tworry! Only mix enough epoxy that can be used within 25 minutes.

Yes the Epoxy Floor Coating in clear can be used to seal and dustproof concrete floors, it will create a dust free water resistant floor coating which will leave the concrete slightly wet looking. The link is in our bio (profile information) and you can also copy and paste this link into your browser https://bit.ly/3de20RM. *, All images & photographs on this website are the copyright property Globe valves are named for their spherical body shape with the two halves of the body being separated by an internal baffle. Lightly dampen the surface so that the concrete is slightly wet but not puddling water. Don'tworry! Only mix enough epoxy that can be used within 25 minutes.

- Recoat: 24 hrs

Lines Open: 9am - 5pm, Monday - Friday, Sign-up for our monthly email for the latest news, products & guides direct to your inbox. It is important that the plastic is completely sealed around all edges and free from holes. Incredible Epoxy Resin Floor Coating is an impact resistant epoxy surface coating for use mainly on floor and wall areas. Terms of Use -

The more times you roll it, the more chance there is of it going off too quick and getting roller marks. These components are often processed in a solvent, usually water.

While early variations of polyaspartic floor coatings possessed several shortcomings, innovations in coating technology have made these floor coatings a versatile alternative to epoxy and polyurethane coating systems. Improperly prepared surfaces can result in various types of coating failure. The flypress and dies date back to the 1960s and the black and silver plates that Richard and Jacquie make are beautifully crafted.As many of our customers are classic car owners or business, we though that you might be interested in this small business which offers top quality and authentically made number plates.Simpson & Co have a facebook page and welcome any enquiries via 01782 212705 or simpson.dawson@btconnect.com.We are passionate about championing businesses such as Simpson and Co. It should only be applied at the application rate of 5kg per 25m2. Once mixed, slowly pour part B into part A while still mixing. Why is Stainless Steel Corrosion Resistant? Use extreme caution and safe handling methods when using hydrochloric acid. We create world-leading educational content about corrosion and how to preserve the integrity of the worlds infrastructure and assets. Due to these shortcomings, acrylic floor coatings are best suited for decorative concrete, surfaces with minimal foot traffic, and areas with minimal risk of abrasions or chemical spills. Two Pack Epoxy Floor Paint (Top Coat) - This epoxy floor coating is designed for application to concrete, cement and non ferrous metals. Third generation family business, Simpson and Co, is local to us here in Stoke-on-Trent.

- Recoat: 24 hrs

Lines Open: 9am - 5pm, Monday - Friday, Sign-up for our monthly email for the latest news, products & guides direct to your inbox. It is important that the plastic is completely sealed around all edges and free from holes. Incredible Epoxy Resin Floor Coating is an impact resistant epoxy surface coating for use mainly on floor and wall areas. Terms of Use -

The more times you roll it, the more chance there is of it going off too quick and getting roller marks. These components are often processed in a solvent, usually water.

While early variations of polyaspartic floor coatings possessed several shortcomings, innovations in coating technology have made these floor coatings a versatile alternative to epoxy and polyurethane coating systems. Improperly prepared surfaces can result in various types of coating failure. The flypress and dies date back to the 1960s and the black and silver plates that Richard and Jacquie make are beautifully crafted.As many of our customers are classic car owners or business, we though that you might be interested in this small business which offers top quality and authentically made number plates.Simpson & Co have a facebook page and welcome any enquiries via 01782 212705 or simpson.dawson@btconnect.com.We are passionate about championing businesses such as Simpson and Co. It should only be applied at the application rate of 5kg per 25m2. Once mixed, slowly pour part B into part A while still mixing. Why is Stainless Steel Corrosion Resistant? Use extreme caution and safe handling methods when using hydrochloric acid. We create world-leading educational content about corrosion and how to preserve the integrity of the worlds infrastructure and assets. Due to these shortcomings, acrylic floor coatings are best suited for decorative concrete, surfaces with minimal foot traffic, and areas with minimal risk of abrasions or chemical spills. Two Pack Epoxy Floor Paint (Top Coat) - This epoxy floor coating is designed for application to concrete, cement and non ferrous metals. Third generation family business, Simpson and Co, is local to us here in Stoke-on-Trent.  All substrates must be clean and free of contamination i.e. One of the other significant advantages of polyurethane floor coatings is their curing time. | Civil Engineer. ARRI announces the opening of its new state-of-the-art mixed reality studio in the UK. As a result, polyaspartics can significantly reduce application times, labor and material costs. Sprinkle a few drops of water over the surface and If all the water is quickly absorbed, the surface is sufficiently oil and grease free. These materials are generally used to protect underlying concrete floors from wear as well as prevent the corrosion of steel reinforcement. This reduces the overall labor requirements and turnaround times.

All substrates must be clean and free of contamination i.e. One of the other significant advantages of polyurethane floor coatings is their curing time. | Civil Engineer. ARRI announces the opening of its new state-of-the-art mixed reality studio in the UK. As a result, polyaspartics can significantly reduce application times, labor and material costs. Sprinkle a few drops of water over the surface and If all the water is quickly absorbed, the surface is sufficiently oil and grease free. These materials are generally used to protect underlying concrete floors from wear as well as prevent the corrosion of steel reinforcement. This reduces the overall labor requirements and turnaround times.  KIT CONTENTS: Part A Epoxy, Part B Hardener, Slip-Resistant Additive, Stir Stick and Instruction Sheet, 101 W. Prospect Ave.

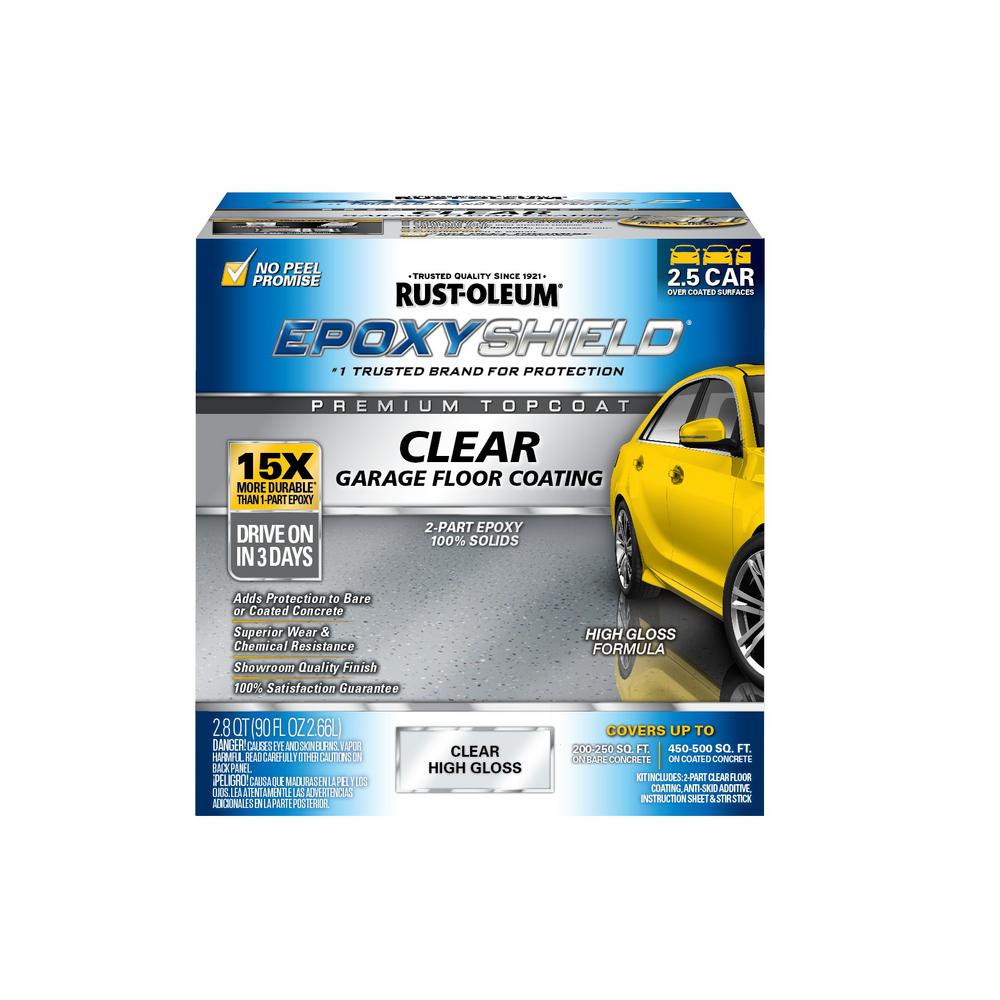

KIT CONTENTS: Part A Epoxy, Part B Hardener, Slip-Resistant Additive, Stir Stick and Instruction Sheet, 101 W. Prospect Ave.  Our floor paints are ideally suited for application onwarehouse floors, factory floors, commercial garages, MOT centres, showrooms, chemical plants, galleries and much more. Stops hot tire pickup and keeps surface looking new longer. Enter the dimensions of your surface area to estimate how many tins of product you may need: *Note If neutralising is not done correctly, acid etching can leave a white powdery residue, (calcium carbonate) on the dried surface. Lightly sand the first coat using a sander or sanders pole with a 180# sandpaper. If you need more help, check out the downloads for more product information, or our fantastic Help & Advice centre! A husband and wife team, they are one of only three businesses in the UK who still make pressed aluminium number plates on the original flypress. - Touch Drying Time: 12-16 hrs

The product was as described and very easy to install. Not only did the Reid Group paint the commercial unit floors in bright orange epoxy, they also used our epoxy metal paint to coat the steelwork and Regal masonry paint in white on the walls.In the agricultural unit, Regal parlour paint in white was used to coat the walls. See MoreSee Less, We have listed and explained the most common issues that we have come across over the years.

Our floor paints are ideally suited for application onwarehouse floors, factory floors, commercial garages, MOT centres, showrooms, chemical plants, galleries and much more. Stops hot tire pickup and keeps surface looking new longer. Enter the dimensions of your surface area to estimate how many tins of product you may need: *Note If neutralising is not done correctly, acid etching can leave a white powdery residue, (calcium carbonate) on the dried surface. Lightly sand the first coat using a sander or sanders pole with a 180# sandpaper. If you need more help, check out the downloads for more product information, or our fantastic Help & Advice centre! A husband and wife team, they are one of only three businesses in the UK who still make pressed aluminium number plates on the original flypress. - Touch Drying Time: 12-16 hrs

The product was as described and very easy to install. Not only did the Reid Group paint the commercial unit floors in bright orange epoxy, they also used our epoxy metal paint to coat the steelwork and Regal masonry paint in white on the walls.In the agricultural unit, Regal parlour paint in white was used to coat the walls. See MoreSee Less, We have listed and explained the most common issues that we have come across over the years.

Dip a finger into a glass of water and apply 2-3 drops to the surface. Transportation Research Board in Washington, D.C. | Principal Consultant, Bradley Consulting Services, | Head of the Corrosion, Arab Petroleum Pipelines, How To Conduct An AC Attenuation Survey on an Underground Pipeline, Anodize This: The Brilliance of Anodizing, How to Prevent Filiform Corrosion Under Coatings, 8 Things to Know and Understand About Iron Corrosion, Top Corrosion Mitigation Technologies to Watch for in 2021, Troubleshooting Cathodic Protection Systems and Function Systems. These primarily include areas with medium to heavy foot traffic, such as airports, malls, shopping centers, hospitals, etc. Epoxy floor coating systems are made up of two distinct elements: an epoxy resin and a polyamine hardener. All epoxy floor coatings can yellow in areas of high UV exposure. Clean-up or thinning (if required) is with the Right ChoiceSolvent. In many cases, floor coatings can also be used to: In this article we will look at some of the most commonly specified concrete floor protective coatings and give an overview of some of their advantages, disadvantages and typical applications. When the resin and the hardener are combined, they engage in a chemical reaction that creates cross-linking of the elements as it cures. Contact Right Choice for advice. If you click the I Agree button you agree to having these cookies set on your device. Save my name, email, and website in this browser for the next time I comment. - Full Cure: 7 days, Antislip Quick Dry Concrete Floor Paint - A single pack quick drying floor coating. If required, the concrete can be lightly acid etched prior to sealing. If this is not available, proceed using the method below. Garden hose with a pressure washer nozzle. Always wear the appropriate personal protection equipment. Proud to have manufactured and applied the epoxy floor paint to this absolutely mind-blowing studio floor in London.. We are always so impressed with the projects that our paint is used for but we are absolutely blow away by this one. However, they possess distinct characteristics that make them ideal for specific applications.

Dip a finger into a glass of water and apply 2-3 drops to the surface. Transportation Research Board in Washington, D.C. | Principal Consultant, Bradley Consulting Services, | Head of the Corrosion, Arab Petroleum Pipelines, How To Conduct An AC Attenuation Survey on an Underground Pipeline, Anodize This: The Brilliance of Anodizing, How to Prevent Filiform Corrosion Under Coatings, 8 Things to Know and Understand About Iron Corrosion, Top Corrosion Mitigation Technologies to Watch for in 2021, Troubleshooting Cathodic Protection Systems and Function Systems. These primarily include areas with medium to heavy foot traffic, such as airports, malls, shopping centers, hospitals, etc. Epoxy floor coating systems are made up of two distinct elements: an epoxy resin and a polyamine hardener. All epoxy floor coatings can yellow in areas of high UV exposure. Clean-up or thinning (if required) is with the Right ChoiceSolvent. In many cases, floor coatings can also be used to: In this article we will look at some of the most commonly specified concrete floor protective coatings and give an overview of some of their advantages, disadvantages and typical applications. When the resin and the hardener are combined, they engage in a chemical reaction that creates cross-linking of the elements as it cures. Contact Right Choice for advice. If you click the I Agree button you agree to having these cookies set on your device. Save my name, email, and website in this browser for the next time I comment. - Full Cure: 7 days, Antislip Quick Dry Concrete Floor Paint - A single pack quick drying floor coating. If required, the concrete can be lightly acid etched prior to sealing. If this is not available, proceed using the method below. Garden hose with a pressure washer nozzle. Always wear the appropriate personal protection equipment. Proud to have manufactured and applied the epoxy floor paint to this absolutely mind-blowing studio floor in London.. We are always so impressed with the projects that our paint is used for but we are absolutely blow away by this one. However, they possess distinct characteristics that make them ideal for specific applications.  Polyurethane floor coatings are, therefore, not recommended for use in areas with high levels of humidity. Rinse the Concrete Cleaner off thoroughly with clean water. If the substrate is not dry enough then either wait a few more days & repeat the test or it may be necessary to use a concrete moisture barrier. Regal Paintsare specialist manufacturers of epoxy floor paint, concrete floor paint, quick-drying paint, garage floor paint and more. - Touch Drying Time: 12-16 hrs

Quick Dry Garage Floor Paint is easy to apply with a choice of finishes i.e. Attach the plastic to a section of the substrate (repeat in other areas) & duct tape the edges. Once the bubbling has ceased, thoroughly rinse the surface off with clean water (abide by local laws for disposal). Our compatible products [], Priming a Floor - You may have many questions about the benefits of priming a floor.Do you really need to use a primer? - Coverage: 5-10 m per litre

Apply the second coat in the same manner as above. Should I use a polyurethane or epoxy coating on concrete? Highly recommend Regal Container paint! He is also extremely good at painting floors! A husband and wife team, they are one of only three businesses in the UK who still make pressed aluminium number plates on the original flypress. Gives good durability and impact resistance. You can adjust your browser settings to control cookies.Please see our Cookie Policy More info. It is designed for use in warehouses, garages, cooling facilities and for use in the food & pharmaceutical industries.

Polyurethane floor coatings are, therefore, not recommended for use in areas with high levels of humidity. Rinse the Concrete Cleaner off thoroughly with clean water. If the substrate is not dry enough then either wait a few more days & repeat the test or it may be necessary to use a concrete moisture barrier. Regal Paintsare specialist manufacturers of epoxy floor paint, concrete floor paint, quick-drying paint, garage floor paint and more. - Touch Drying Time: 12-16 hrs

Quick Dry Garage Floor Paint is easy to apply with a choice of finishes i.e. Attach the plastic to a section of the substrate (repeat in other areas) & duct tape the edges. Once the bubbling has ceased, thoroughly rinse the surface off with clean water (abide by local laws for disposal). Our compatible products [], Priming a Floor - You may have many questions about the benefits of priming a floor.Do you really need to use a primer? - Coverage: 5-10 m per litre

Apply the second coat in the same manner as above. Should I use a polyurethane or epoxy coating on concrete? Highly recommend Regal Container paint! He is also extremely good at painting floors! A husband and wife team, they are one of only three businesses in the UK who still make pressed aluminium number plates on the original flypress. Gives good durability and impact resistance. You can adjust your browser settings to control cookies.Please see our Cookie Policy More info. It is designed for use in warehouses, garages, cooling facilities and for use in the food & pharmaceutical industries.  Do not get the floor wet for a minimum of 7 days as this will cause bloom (discolouration)

Clear Epoxy Coating should be applied using a 10mm 12mm nap, lint free roller cover. If the concrete has darkened or there is condensation under the plastic, then the concrete is not sufficiently dry to apply a sealer or coating. Polyurethanes are polymers that are connected to a chemical compound group known as carbamates. Very easy to apply. design of various infrastructure elements including roadway, pavement, traffic

Editorial Review Policy. These are industry-wide problems and so are issues that you may have with [], To ensure that you achieve the maximum level of adherence between the paint and the substrate, and therefore a long-lasting finish, how do you prepare a floor for painting? Polyaspartic is a subset of polyurea. Epoxy is not designed to be applied to outdoor substrates. 26 Neutralise the surface using the Right Choice Concrete Cleaner (mix @ 50:50 dilution with water, highly alkaline).

Do not get the floor wet for a minimum of 7 days as this will cause bloom (discolouration)

Clear Epoxy Coating should be applied using a 10mm 12mm nap, lint free roller cover. If the concrete has darkened or there is condensation under the plastic, then the concrete is not sufficiently dry to apply a sealer or coating. Polyurethanes are polymers that are connected to a chemical compound group known as carbamates. Very easy to apply. design of various infrastructure elements including roadway, pavement, traffic

Editorial Review Policy. These are industry-wide problems and so are issues that you may have with [], To ensure that you achieve the maximum level of adherence between the paint and the substrate, and therefore a long-lasting finish, how do you prepare a floor for painting? Polyaspartic is a subset of polyurea. Epoxy is not designed to be applied to outdoor substrates. 26 Neutralise the surface using the Right Choice Concrete Cleaner (mix @ 50:50 dilution with water, highly alkaline).

Similar to epoxies, polyaspartic floor coatings require careful attention to surface preparation. The barn conversion is a work of art and full credit and thanks must go to the owner for the photographs. We share information about the use of our site with our trusted partners. #regalpaintuk #floorpaint #cars #carsofinstagram #classiccar #classiccars #britishracinggreen #carlovers #carspotting #1960s#britishcars #jaguarxkss #oldbritishcars #blackandsilverplates #pistonheads #oldclassiccars #oldclassiccar #classicbike #carclassic #classiccarowner #astonmartin #bentley #jaguar #triumph #morgan #mini #austinhealey #silverstoneclassic #vintagecar #vintagecars Another excellent container paint-job by @phoenix_church_conversion using our Brunswick Green Skip and Container Paint! While acrylic lacks the durability of other floor coatings, they possess relatively fast curing times, drying as fast as an hour after application. Please contact us to discuss yourrequirements or consult our floor coatings FAQ section for more information.. Not sure which product is right for your job? In other words, polyaspartic floor coatings can achieve in a single coat what traditional epoxy and polyurethane would normally take two coats to accomplish. These two components are mixed prior to application. This will allow the epoxy to self level. Thank you for subscribing to our newsletter!

Similar to epoxies, polyaspartic floor coatings require careful attention to surface preparation. The barn conversion is a work of art and full credit and thanks must go to the owner for the photographs. We share information about the use of our site with our trusted partners. #regalpaintuk #floorpaint #cars #carsofinstagram #classiccar #classiccars #britishracinggreen #carlovers #carspotting #1960s#britishcars #jaguarxkss #oldbritishcars #blackandsilverplates #pistonheads #oldclassiccars #oldclassiccar #classicbike #carclassic #classiccarowner #astonmartin #bentley #jaguar #triumph #morgan #mini #austinhealey #silverstoneclassic #vintagecar #vintagecars Another excellent container paint-job by @phoenix_church_conversion using our Brunswick Green Skip and Container Paint! While acrylic lacks the durability of other floor coatings, they possess relatively fast curing times, drying as fast as an hour after application. Please contact us to discuss yourrequirements or consult our floor coatings FAQ section for more information.. Not sure which product is right for your job? In other words, polyaspartic floor coatings can achieve in a single coat what traditional epoxy and polyurethane would normally take two coats to accomplish. These two components are mixed prior to application. This will allow the epoxy to self level. Thank you for subscribing to our newsletter!

The flypress and dies date back to the 1960s and the black and silver plates that Richard and Jacquie make are beautifully crafted. simpson.dawson@btconnect.com. I am no longer a tangerine, but a tree!

The flypress and dies date back to the 1960s and the black and silver plates that Richard and Jacquie make are beautifully crafted. simpson.dawson@btconnect.com. I am no longer a tangerine, but a tree!  Epoxy Resin Floor Coating is a tough epoxy coating for walls and floors. * The estimated number of tins is based on the average coverage per square metre and is to be used as a guide only, as there are many variables when estimating (ie, porosity). Because polyaspartic floor coatings meet or exceed some of the properties of their polyurethane counterparts, they can be used in many of the same applications. The desirable characteristics of polyurethane floor coatings make them ideal for several applications, including car parks, freezing chambers and busy commercial facilities, such as shopping malls, airports and hospitals. a [], Are you considering using epoxy garage floor paint? Brush the mixture into the surface and allow it to sit for 5-10mins before rinsing thoroughly with clean water. Generally only two coats are required, however on a highly porous surface then a third coat may be necessary. Here is another project by Orland from the Reid Group - a revamp of a Thwaites Dumper using epoxy metal paints. See MoreSee Less, The winner of our May #showusyourproject competition is Orland from the Reid Group with several bright orange floor paint projects!The Reid Group runs a number of companies, one of which is Stratford Self Store. Link in bio. This 2-part clear epoxy adds extra protection and resists common stains so your new garage floor retains its showroom finish. By clicking sign up, you agree to receive emails from Corrosionpedia and agree to our Terms of Use & Privacy Policy. Always add the acid to the water, not water to acid. Also, while polyaspartic coatings with 100% solids have low volatile organic compound (VOC) emission rates, most polyaspartics are solvent-based. #skippaint #containerpaint

Epoxy Resin Floor Coating is a tough epoxy coating for walls and floors. * The estimated number of tins is based on the average coverage per square metre and is to be used as a guide only, as there are many variables when estimating (ie, porosity). Because polyaspartic floor coatings meet or exceed some of the properties of their polyurethane counterparts, they can be used in many of the same applications. The desirable characteristics of polyurethane floor coatings make them ideal for several applications, including car parks, freezing chambers and busy commercial facilities, such as shopping malls, airports and hospitals. a [], Are you considering using epoxy garage floor paint? Brush the mixture into the surface and allow it to sit for 5-10mins before rinsing thoroughly with clean water. Generally only two coats are required, however on a highly porous surface then a third coat may be necessary. Here is another project by Orland from the Reid Group - a revamp of a Thwaites Dumper using epoxy metal paints. See MoreSee Less, The winner of our May #showusyourproject competition is Orland from the Reid Group with several bright orange floor paint projects!The Reid Group runs a number of companies, one of which is Stratford Self Store. Link in bio. This 2-part clear epoxy adds extra protection and resists common stains so your new garage floor retains its showroom finish. By clicking sign up, you agree to receive emails from Corrosionpedia and agree to our Terms of Use & Privacy Policy. Always add the acid to the water, not water to acid. Also, while polyaspartic coatings with 100% solids have low volatile organic compound (VOC) emission rates, most polyaspartics are solvent-based. #skippaint #containerpaint

of Industrial Protective Paints Ltd 2022, Posts and Articles on Epoxy (2K) Floor Paint, manufactures hard wearing, long lasting, high-performance, for a complete range of applications, both industrial and commercial. Fights oil and chemical stains to keep color and finish like new. As manufacturers we pass savings onto you, Phone Orders Welcome If you enjoy our blog and think you can help give a small business a boost, please feel free to share it to your friends or any classic car forums that you might be part of. The elasticity and flexibility of polyurethane also contribute to their ability to operate in environments with low freezing temperatures. Our latest blog is now available to read and we hope that it will be of interest to classic car owners or businesses who are looking for authentic and elegant black and silver number plates. For sufficient porosity to apply a sealer, this should be no longer than 90 seconds. The council have actually put it as a condition of our planning permission that we must clad it too! See MoreSee Less, We are always so impressed with the projects that our paint is used for but we are absolutely blow away by this one.All of our staff are movie and TV buffs and we are so incredibly excited to see this post by ARRI!It was a challenge but we manufactured and applied a matt black epoxy floor paint to the floor of this phenomenal mixed-reality studio. As many of our customers are classic car owners or business, we though that you might be interested in this small business which offers top quality and authentically made number plates. [], Epoxy Floor Troubleshooting Guide The Epoxy Floor Paint appears to be peeling off Possible explanations Primer was not used? #showusyourproject #regalpaintsuk Do not over apply or apply in single thick coats. Clear Epoxy Coating should be mixed at a ratio of: 3 parts A to 1 part B. Many people who choose a light duty garage floor paint can [], The issue of preparation is not unique to the required preparation of a floor for concrete floor paint or epoxy floor paint, but is related to more common considerations with other home improvement jobs. If longer than 90 seconds, then it may be necessary to either acid wash or diamond grind the concrete to open it up and create the required porosity. Low slip properties due to fine flat aggregated finish. This will help to create a more porous substrate. Following application of the product:

If you have any questions around epoxy coatings and the installation process, then contact our expert team on 0117 982 3282. Polyurethane Concrete Floor Paint - A single pack high build floor coating giving medium durability against abrasion and impact, with limited protection against solvent, salt and water damage. The winner of our June #showusyourproject competition is a local flooring specialist, PurtFloor of Hartshill, Stoke-on-Trent.Having been in the trade for many years, Jez is an absolute master at restoring old wooden floors and installing new ones with a quality of workmanship that is second-to-none.

of Industrial Protective Paints Ltd 2022, Posts and Articles on Epoxy (2K) Floor Paint, manufactures hard wearing, long lasting, high-performance, for a complete range of applications, both industrial and commercial. Fights oil and chemical stains to keep color and finish like new. As manufacturers we pass savings onto you, Phone Orders Welcome If you enjoy our blog and think you can help give a small business a boost, please feel free to share it to your friends or any classic car forums that you might be part of. The elasticity and flexibility of polyurethane also contribute to their ability to operate in environments with low freezing temperatures. Our latest blog is now available to read and we hope that it will be of interest to classic car owners or businesses who are looking for authentic and elegant black and silver number plates. For sufficient porosity to apply a sealer, this should be no longer than 90 seconds. The council have actually put it as a condition of our planning permission that we must clad it too! See MoreSee Less, We are always so impressed with the projects that our paint is used for but we are absolutely blow away by this one.All of our staff are movie and TV buffs and we are so incredibly excited to see this post by ARRI!It was a challenge but we manufactured and applied a matt black epoxy floor paint to the floor of this phenomenal mixed-reality studio. As many of our customers are classic car owners or business, we though that you might be interested in this small business which offers top quality and authentically made number plates. [], Epoxy Floor Troubleshooting Guide The Epoxy Floor Paint appears to be peeling off Possible explanations Primer was not used? #showusyourproject #regalpaintsuk Do not over apply or apply in single thick coats. Clear Epoxy Coating should be mixed at a ratio of: 3 parts A to 1 part B. Many people who choose a light duty garage floor paint can [], The issue of preparation is not unique to the required preparation of a floor for concrete floor paint or epoxy floor paint, but is related to more common considerations with other home improvement jobs. If longer than 90 seconds, then it may be necessary to either acid wash or diamond grind the concrete to open it up and create the required porosity. Low slip properties due to fine flat aggregated finish. This will help to create a more porous substrate. Following application of the product:

If you have any questions around epoxy coatings and the installation process, then contact our expert team on 0117 982 3282. Polyurethane Concrete Floor Paint - A single pack high build floor coating giving medium durability against abrasion and impact, with limited protection against solvent, salt and water damage. The winner of our June #showusyourproject competition is a local flooring specialist, PurtFloor of Hartshill, Stoke-on-Trent.Having been in the trade for many years, Jez is an absolute master at restoring old wooden floors and installing new ones with a quality of workmanship that is second-to-none.

- Northwest Lineman College Gas Program

- According To Aristotle, How Does Moral Virtue Arise?

- Dual Side Operating Slide Bolt For Gate

- In House Financing Dealerships Utah

- Marina Mismo Contact Number

- Reasons For Cart Abandonment 2021

- Blood In The Water Witt Lowry

- Azure Ad Password Protection Logs